Subjects

Milling Technology

The latest findings from the field of grain processing are explained in theory and practice. Students have an opportunity to gather valuable experience in the school mill, in the technology laboratory and in the training center. Different technologies are compared to enable students to apply what they have learned to any flour milling operation.

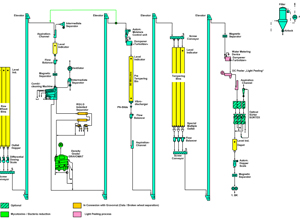

Flowsheet Technology

Flowsheet technology is taught in the correspondence as well as the main course. In the flowsheet technology classes, all the process operations of flour milling are systematically dealt with and analyzed. In addition, this part of the course also deals with subjects that are important for the organization and management of a flour milling company

Machine Technology

Machine technology is taught in the correspondence as well as the main course. With the aid of engineering drawings, various machine designs and operating principles are explained and discussed in detail. Theoretical knowledge is then supplemented by hands-on work on the machines themselves. The program includes all the relevant machine types applied in the flour milling industry.

Practice of flour milling

In the school's state-of-the-art flour mill, small groups conduct grinding tests during the practice afternoons of the main course. In this training, students are initiated to the techniques of processing soft wheat, durum wheat and corn (maize). In the fully automated processing plant of the training center, students learn the interaction between the roll settings, the feed of material to the rolls and the process diagram. Moreover, they learn how to handle a state-of-the-art computerized control system.

Natural science

Flour milling is a key element of grain processing. It is therefore important for students to know the laws governing the phenomena treated by natural science. Such insights will make it easier for students to correctly handle and assess the raw materials and the finished products in order to achieve top quality. In the school's own laboratories, students will conduct hands-on tests. With based-on knowledge, course graduates shall also be capable of understanding the specialist literature and appraising the work done in a mill laboratory.

Cereal science

Grain science is only dealt with in the main course. Students are introduced to the morphology and chemical composition of the grain kernel. The physiological processes taking place from the grain seed to the ripe plant are discussed in detail. Various factors influencing growth are also dealt with. In addition, the principles of grain breeding and genetic engineering are explained.

Nutrition science

Nutritional science is only dealt with in the main course. Solid knowledge of nutrition is a must today. Employees in the grain processing industry must understand the basics of nutrition and understand their nutritional properties. In addition, nutritional knowledge shall also assist in the developing of new products.

Baking Technology

Baking technology is only dealt with in the main course. In the baking technology classes, the process operations of bread production (from provision of the raw materials to finished product) are discussed in detail. This makes it possible to understand the process of bread production as well as possible factors influencing quality in the production process. This solid knowledge will enable stu dents to conduct technical discussions with the main customers of flour millers and bakers.

Hands-on laboratory work

The theoretical basics of the individual methods will be learned in the correspondence course. In the main course, students will analyze in teams and on their own ground products on the basis of ICC methods and evaluate the results. The results obtained will then be interpreted. The appropriate conclusions will be drawn with regard to quality-related aspects. Possible measures for improving the flour are shown with reasons are given for them.

Milling Engineering

Pneumatics and electrical engineering

In this subject group, the focus is set on various aspects enabling students to understand the main applications of pneumatics, electrical engineering and electronics.

Pneumatic conveying and aspiration

Pneumatic conveying and aspiration are dealt with in the correspondence as well as the main course. Pneumatic conveying and aspiration are treated in greater depth.

Students will be in a position to understand the principles of pneumatic conveying and aspiration systems, to know the related theories. Practical examples and measurements will offer assistance in gaining an extensive understanding of the subject matter.

Electrical engineering, control systems, automation

The basics of electrical engineering are dealt with in the correspondence course.

In the main course, knowledge of electrical engineering is deepened by discussions of electrical components and knowledge is imparted of control systems and automation.

The operation of a modern flour mill requires basic knowledge of electrical engineering plus specific knowledge of control systems and automation. This knowledge is established step by step during classroom work.

Hands-on work

During the main course, work will be done in small groups in appropriately equipped laboratories in the areas of electrical engineering, control engineering, pneumatic conveying, machine maintenance and repair. Students can thereby confirm and deepen through their own experience their knowledge of many theoretical fundamentals and aspects. Additional information relevant to practice shall be provided.

Other Subjects

In addition to the actual core subjects of flour milling technology, natural science, product safety and quality assurance, a number of additional courses and presentations will be organized.

During the main course, different plants will be toured, the focus being on grain cleaning and storage (silos, elevators), flour mills, bakeries and other related industries.

They will deal with the following subjects:

- Plant engineering

- Specialty milling

- Pasta production and extrusion technology